I-hydraulickufanelekile yinto yokudibanisa phakathi kombhobho we-hydraulic kunye nombhobho we-hydraulic, okanye phakathi kombhobho kunye ne-hydraulic element. I-hydraulickufanelekile iqulethe i-hydraulicizixhobot ukwenzela ithumbu kunye nehydraulicizixhobo ngenxaindibano yetyhubhu, i-hydraulic hose connector idibanisa icandelo elinye le-hose ye-hydraulic (ebizwa ngokuba ngumsila womsila) kunye nesinye isiphelo kwamanye amacandelo (i-terminals) ukuqinisekisa ukuhambelana kunye nokutywinwa okungenakuvuza ngokudibanisa namanye amacandelo, i-terminal ye-hose ye-hydraulic hose joint kufuneka ibe iyilwe ngokomgangatho wojongano lwehlabathi. Umsebenzi ophambili we-terminal kukuqinisekisa ukutywinwa kwexesha elide phakathi kwe izixhobokunye nethumbu.

Ukusuka kwi-interface inokwahlulwa ngokwezi fom zilandelayo:

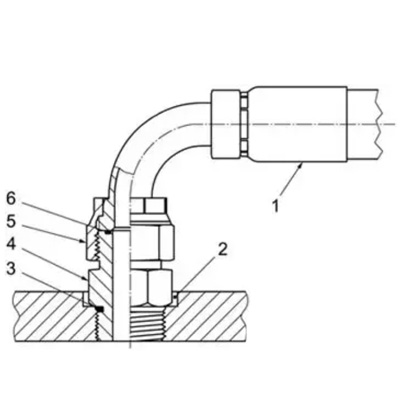

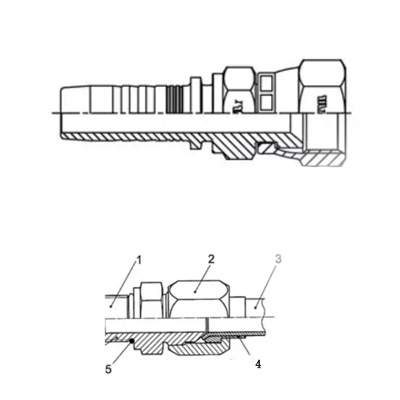

1.I-O-ring face seal hoseizixhobo

1.Hose couplings 2. IoliIzibuko3. O-ringi 4.Iiadaters5. Nuts 6. O-ring

xa i-nut 5 ikrwelwe kumsonto wangaphandle weizixhobo, kunye nokunyuka komzuzu wokuqinisa, ubuso bokuphela kombhobhoizixhobokwaye iiiadaptha(isiqwenga sesi-4) sicinezela, i-o-ring ye-4-end face of theizixhoboivelisa i-elastic deformation, kwaye idibanisa ngokupheleleyo ubuso be-4-isiphelo sesiqhekeza 6 kunye nesiqwenga se-4 kwaye ivelise uxinzelelo lokutywinwa.

Ingqwalasela ekhethekileyo kufuneka ihlawulwe kwinkqubo yokufakela, khangela ikhonkco lokutywina ngaphambi kokufakwa.

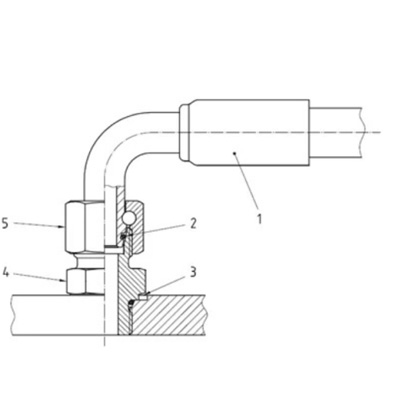

2.24 ° taper seal ekupheleni umbhobho isinxibelelanisi

- I-Hose couplings 2. I-O-ring 3. IoliIzibuko 4. Iadaptha 5. Indongomane

xa i-nut 5 ikrwelwe kumsonto wangaphandle we iadaptha -Icandelo 4) , umphezulu we-cone wangaphandle we-hosekufanelekile kunye nomphezulu wekhowuni yangaphakathikufanelekile I-b-Partdy (inxalenye ye-4) uqhagamshelwano kunye noxinzelelo kunye nokunyuka kwexesha lokuqina, i-o-ring ye-conical surface yangaphandle ye-hoseizixhobo I-1 ivelisa i-elastic deformation, idibanisa ngokupheleleyo kunye ne-conical surfaces yecandelo lesi-6 kunye necandelo le-4 kwaye ivelise uxinzelelo olukhulu, olusebenza njengetywina, kwaye uxinzelelo phakathi kwemigangatho ye-conical inkulu ngenxa yesenzo se-lever ye-conical surfaces, umphumo wokutywina ungcono kwithiyori.

Ingqwalasela ekhethekileyo kufuneka ihlawulwe kwinkqubo yokufakela, khangela ikhonkco lokutywina ngaphambi kokufakwa.

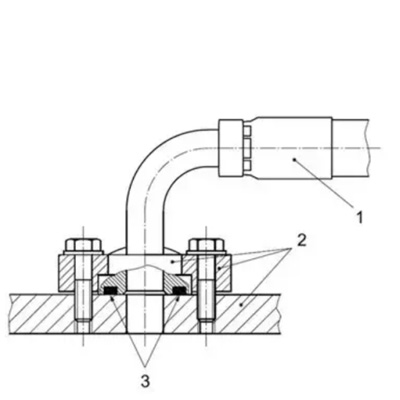

3.Ufakelo lwemibhobho yokuphela kweFlanged

I-1.I-Hose couplings 2. I-oil nozzle, intloko ye-flange, i-flange ye-pressure plate 3.Intloko ye-flange ye-hose joint icinezelwe kwi-orifice yeoli ngeplate yoxinzelelo lwe-flange.

Xa umzuzu wokuqiniswa kwebholithi ukhula, ibholithi ivelisa amandla amakhulu okuqinisa kwangaphambili. I-pre-tighten force ye-bolt idlula kwi-plate yoxinzelelo lwe-flange, icinezela intloko ye-flange ngokuqinileyo kwi-orifice yeoli, i-o-ring (Icandelo lesi-3) kwintloko ye-flange icinezelekile ukuba ikhubaze, kunye ne-hose joint -Partpart 1) inonxibelelwano olwaneleyo phakathi kobuso besiphelo seflange kunye nomphezulu we-oyile ye-oyile ukuvelisa uxinzelelo, olusebenza njengetywina, ngenxa yokusetyenziswa kweebholiti zamandla aphezulu, uxinzelelo phakathi koqhagamshelwano. imiphezulu iphezulu kakhulu kwaye isiphumo sokutywina sihle kakhulu kwithiyori.

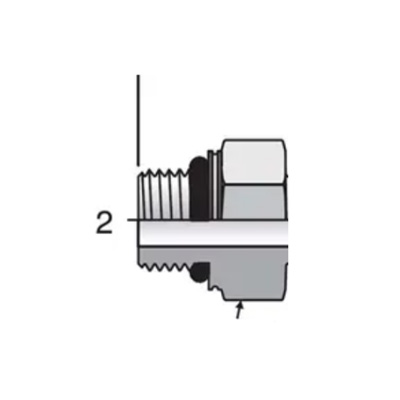

4.Ukufakwa kombhobho we-stud end

Ingcambu yomsonto weiadapthainikwe iwasha yodidi lwe-O. Xa i-joint idibaniswe ne-oil port ngokusebenzisa intambo, i-O-type ring ibambelela ekupheleni kobuso be-oil port ukuze idlale indima yokutywina.

5.37 ° yavutha ithumbu ekupheleni isinxibelelanisi

1. Ukudityaniswa kombhobho 2. I-NUTS 3. Ipayipi yentsimbi 4.

xa i-nut ye-2 igxothwe kwintambo yangaphandle ye-joint body (iqhekeza 1), kunye nokunyuka kwexesha lokuqina, i-cone yangaphandle ye-cone yoqhagamshelwano kunye ne-compact kunye ne-cone yangaphakathi yombhobho wensimbi (iqhekeza 3 ), i-hose joint 1 isiqwenga se-3 i-cone yoqhagamshelwano olupheleleyo kwaye ivelise uxinzelelo olukhulu, idlale indima yokutywina, ngenxa ye-cone ye-lever, uxinzelelo phakathi kwe-cone lukhulu. Kwinkqubo yokukhetha umbhobho we-hydraulic joint, kufuneka sithathele ingqalelo ubuninzi boxinzelelo olusebenzayo, ubushushu bokusebenza, ubungakanani bombhobho, ubungakanani bombhobho ofanelekileyo, nokuba ukufakela kukulungele, uqoqosho kunye nezinye izinto. Uxinzelelo oluphezulu lokusebenza komdibaniso aluyi kuba ngaphantsi koxinzelelo oluphezulu lomsebenzi we-hose.

Ixesha lokuposa: Nov-28-2023